One pleasure of living in Japan is being able to pop into a convenience store at any hour to pick up a snack, pay a utility bill, or buy some essential thing that you really need right now. Japan borrowed the convenience store concept from the United States in the 1970s and, in the decades since, has made it uniquely its own. There are some 58,000 konbini in Japan today, selling a remarkable variety of foods, beverages and dry goods from compact spaces. Annual sales are in the neighborhood of eleven trillion yen.

But like much of Japan's retail sector, the country's convenience stores are struggling with a labor shortage, driven in part by declining birth rates. Stores are finding it difficult to operate on the 24/7/365 schedules they're famous for, and labor costs, thanks to low supply, are rising.

As part of its broader effort to make retailers more competitive through adoption of latest-generation technology, Japan’s Ministry of Economy, Trade and Industry (METI) has entered into an agreement with five of the country's largest convenience store companies to implement Radio-Frequency Identification (RFID) technology in stores by 2025. By applying an RFID-enabled tag embedded with a unique digital identity to every product, store owners will realize two transformations: faster, fully automated shopping, and dramatically improved inventory and supply chain management.

Labor shortages and supply chain challenges aren't unique to Japan, of course. Grocers in the U.S. and elsewhere face many of the same dynamics, and the wise ones are keeping an eye on Japan's RFID implementation. Like sushi, anime, and emoji, what's considered "Japanese" today is likely to be a global phenomenon in the near future.

Implementing the five-second checkout

While each brand taking part in the Japanese government's project will implement RFID in its own way, the technology is expected to enable greater self-service throughout convenience stores, starting on the shelves. Using an app on their mobile phones, shoppers can scan products to get detailed information about prices, ingredients, sourcing, and more. At checkout, RFID enables all of a shopper's items to be rung up automatically and instantly, rather than item-by-item, as with barcodes. Charges can be billed to shoppers' credit cards via their mobile apps. The entire process takes about five seconds—no store employee necessary. How do you prevent theft? Simple: If a scanner at the exit detects an RFID tagged item that hasn't been paid for, the store's doors stay closed.

Greater visibility into inventory

The shopping and checkout experience is RFID's most visible benefit to convenience store customers, but even more of RFID's potential value lies behind the scenes, in its ability to build savings and efficiency into store inventories and supply chains.

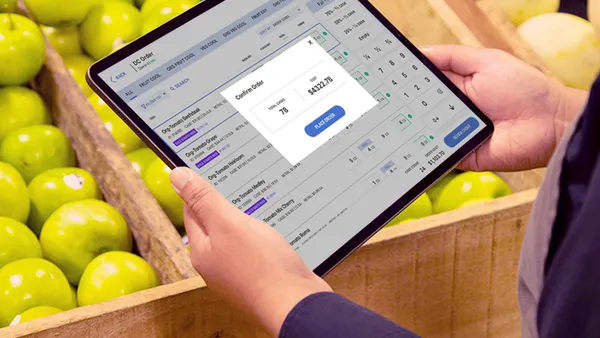

By making every product visible to a store's online inventory management system, RFID tagging provides a much more accurate picture of what's on the shelves and in stockrooms, substantially improving understocking and overstocking. It can provide detailed data on demand for individual products in specific stores and regions, enabling more efficient ordering, planning, and pricing. A recent survey by the IBM Institute for Business Value pulled 1,900 executives who are leaders in the areas of supply chain, operations, and customer engagement showed that they expect intelligent automation to increase annual revenue growth by 10 percent. RFID tagging captures and creates the data that fuels intelligent automation.

RFID tagging also enables unprecedented traceability in the event of a product recall, enabling item-level tracking from source to retail outlet and sometimes even even into consumers' homes. In some cases, affected food lots have been located in about two seconds, saving critical time and preventing significant volumes of untainted food from being discarded. As more food producers employ blockchain technology to log a product's movement through the supply chain, RFID is the perfect complementary technology, allowing this visibility to be automated at the item level and connecting the information to consumer packaging. Shoppers can scan an item with their phones to follow the product's entire journey—from the field, ranch or sea to the store, and through every processing and transit point in between.

It's worth noting that the possibilities RFID creates for automation, more efficient supply chains, and a better consumer experience aren't restricted to convenience stores and grocery chains. Sodexo Singapore, part of the global food services and facilities management company, recently began installing its RFID-based, self-service SmartFridge vending machines on corporate and government campuses, in schools, and other places where grab-and-go meal options are popular. The company is looking to capture the same benefits as the Japanese government: A faster, more seamless experience for customers, with less waste and fewer attending employees.

A more scalable solution

The METI initiative might be the biggest RFID implementation in convenience stores, but it's not the first. Last year, IBM created a pilot in a convenience store in London to demonstrate RFID's potential for transforming convenience stores’ service and operations.

Probably the best-known experiments with automated, cashier-less stores have been undertaken by retail behemoths Amazon and Alibaba in the U.S. and China, respectively. Notably, however, none of those stores is RFID-based. Amazon Go stores use elaborate sensor arrays and customer-tracking rigs that are expensive and not easily scalable. Alibaba's Hema stores use conventional barcodes, which enable some degree of automation but require line-of-sight, item-by-item scanning, which doesn't save shoppers or store personnel any time. Cost, relative simplicity and ease of adoption give RFID tagging the edge in defining the self-service stores of the near future.

Catching the wave

Item-level RFID tagging is well on its way to mass adoption. Apparel companies were early adopters of the technology, and it is gaining popularity in segments as diverse as beauty, pharmaceuticals, food and beverages, and even commercial aviation. Innovations we've developed at Avery Dennison have eliminated early roadblocks to adoption, like poor read rates on packages containing metal and liquids, or tags that would spark in a microwave. Tag cost has also come down significantly.

Japan's government is betting on RFID to save a uniquely Japanese institution and reinventa sizable share of its grocery landscape by enabling automation and improving efficiency, profitability and sustainability. If the measure succeeds as expected, it's only a matter of time before impossible-to-ignore ROI and a better customer experience compel grocers in the U.S. and elsewhere to do the same.

Join us at GroceryShop and meet the Avery Dennison team to learn about the latest innovations in the food industry, visit us at booth 109.

Julie Vargas is Avery Dennison's global director of RFID market development for food.